|

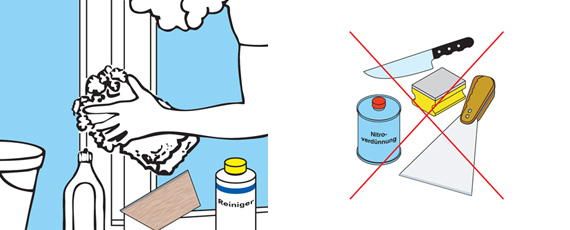

Avoid products containing aggressive solvents and acids that could inflict damage to the the surface of profile (benzole, various paint thinners, toluene, acetic acid, acetone). |

Regular maintenance will ensure a long and trouble-free use. We recommend to perform regularly the following actions:

|

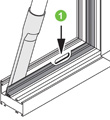

Clean (drain off) drainage slots and clogged weep holes (1) (1x per year) |  |

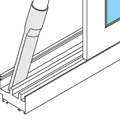

Clean the guide rails in sliding and folding elements. (1x per year) |

Gaskets | Fitting | ||

|

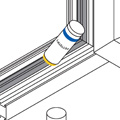

Apply silicone oil to all gaskets, it will lengthen their life and they will not glue together. (1x per year) |  |

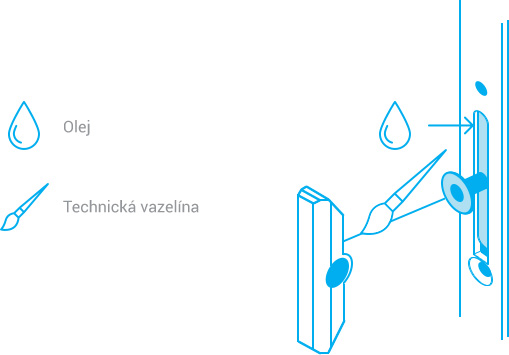

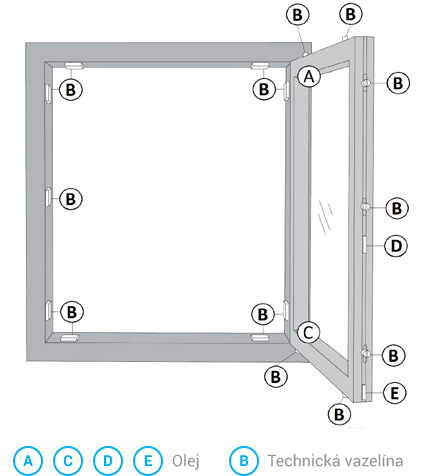

Check the strength of the fitting parts and retighten the loosen screws. For easy running, lubricate all moving parts with oil or technical grease. (1x per year) |

|  |

Application: Oil for the sliding surfaces of the fitting. Technical grease for end pins and their framed counterparts (dovetailing closing parts). Watch the video tutorial. |

All fitting parts must have only a thin layer of oil. When cleaning fittings never use aggressive and acid containing agents that could damage its anti-rust finishing. |

Entrance doors | Cylindrical insert | ||

|

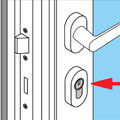

Lubricate the door catch (1) and latch (2) of the lock. (1x per year) |  |

Oil with teflon spray, or graphite powder lubricant (2x per year)

|

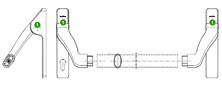

Door with handling (anti panic) push rod | |

|

lubricate right and left joints (1) and check the tightening of screws (2x per year) |

Daily use and external influences (temperature change, sunlight, etc.) may lead to the worsening of your product control. It is mainly worsening of the opening, closing, heavier operation of the handle, and so on. In most cases, however, this is not a defect and after an easy setup, or treatment, it is possible to resolve the problem.

Watch the video tutorials.

Download the manual for the particular product and the fitting